| Fri Jun 02, 2017 | Total posts : 1 |

|  Topic: Independent Beam vs integrated beam in roof slab Topic: Independent Beam vs integrated beam in roof slab

I will be building house. contractor showed me other constructions where beam is integrated in roof slab itself. say for slab of 4.5 inch , remaining 4.5 inch of 9inch beam shows on upper side. I guess this is possible to have to lower side also?

Question : What is advantage / disadvantage of these integrated beams?

|

| |

| Sat Jun 03, 2017 | Post #1 | S L Gupta (Civil Engg)

Join date: Mar 2008 | Dear Sir,

The beam which is above slab have problem to fill the area with any filling material for laying floor in this case you are putting extra load on roof.

The beam under side the slab have more strength but contractor would make shuttering below plane roof and also he will make more arrangement of shuttering and more labor.

Shuttering or form work is the term used for temporary timber,

plywood, metal or other material used to provide support to wet concrete

mix till it gets strength for self support. It provides supports to

horizontal, vertical and inclined surfaces or also provides support to

cast concrete according to required shape and size. The form work also

produces desired finish concrete surface.

Shuttering or form work should be strong enough to support the weight

of wet concrete mix and the pressure for placing and compacting

concrete inside or on the top of form work/shuttering. It should be

rigid to prevent any deflection in surface after laying cement concrete

and be also sufficient tight to prevent loss of water and mortar form

cement concrete. Shuttering should be easy in handling, erection at

site and easy to remove when cement concrete is sufficient hard.

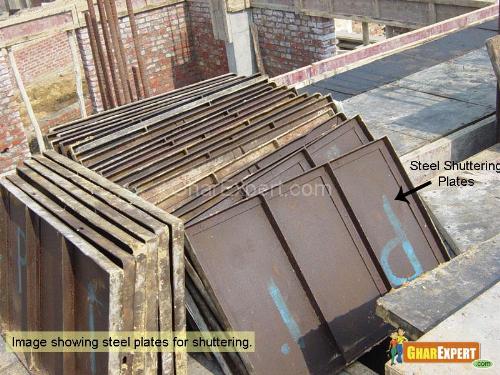

Steel plates for Steel Shuttering

Generally there are three types of shuttering.

- Steel Shuttering

- Wooden Planks Shuttering

- Temporary Brick Masonry Shuttering

Steel Shuttering

Steel

shuttering plate is the best type of shuttering because this is water

tight shuttering which can bear the load of cement concrete placed on

it. This shuttering can be used for horizontal, vertical or any other

shape required for the work. It gives leveled surface which has good

appearance. This shuttering gives good appearance and pattern work

according to architectural drawings. If the plaster is required, the

thickness of plaster will be less. Being water tight shuttering, the

strength of concrete with steel shuttering is comparatively higher.

Shuttering with the help of Steel Plates.

Note: As this is water tight shuttering, it is considered the best shuttering.

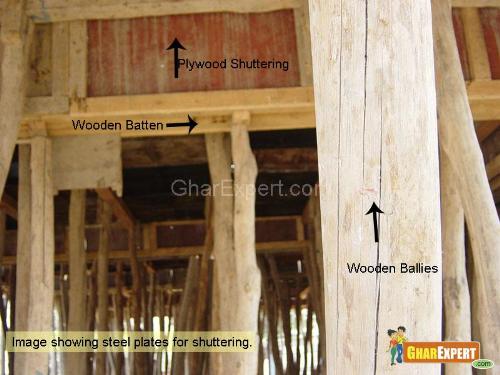

Wooden Plank Shuttering

Generally

wooden planks shuttering is used by contractors because this shuttering

is cheap and easily available. But this type of shuttering effects the

strength of concrete and have some disadvantages which are given below.

Disadvantages

- This is not water tight shuttering as the size and thickness of

planks differ and are not of same size. Due to this difference the water

and cement flow to the ground from joints and reduce the strength of

concrete.

- Bottom level of RCC slab is not in straight line and the surface

being uneven, the thickness of plaster is more which remains weak.

- Due to leakage of cement slurry through joints, earth work below ’'Ballies’ may settle and create problems.

- In some cases wooden planks can not bear the weight of concrete. Due

to low strength there is bending or deflection in wooden planks.

Sometimes the planks may break.

Shuttering done with the help of wooden ballies and batten.

Temporary Brick Masonry Shuttering

In

some cases labor contractor uses Temporary Brick Masonry in mud for

vertical support of sides of beams, fascia etc. This shuttering should

be avoided. This type of shuttering reduces the strength of cement

concrete by soaking cement slurry. Also no proper compaction is made as

this shuttering does not bear the pressure of vibrator. The surface of

cement concrete given by this type of shuttering is uneven and the

thickness of plaster is increased.

Precautions for Vertical Supports for RCC Beams, Slabs etc

- The ’'Ballies’ used for vertical support should not be less than 6'' dia and these should be in one length without joints.

- Never allow bricks support of more than one or two bricks below a 'balli' to make required height.

- Cross Ballies or bracing should be done for better support to beam as well as slab.

- The wooden batten used below the plate should not be less than 5'' in height.

- At the time of concreting one carpenter with helper having spare

ballies, nails etc. should be deputed for watching any disturbances in

ballies under shuttering.

Precautions for Cantilever slabs and Beams

- While doing shuttering of a cantilever part, outer edge of shuttering is 1” to 2'' higher than inner edge with the wall.

- The bracing of vertical supports for cantilever portion should be tied to vertical supports of internal slab.

- The concrete should be laid on cantilever portion very gently.

- The shuttering should be removed after 28 days.

Recommended Period for Removal of Shuttering

- 48 hours for sides of foundations, columns, beams and walls.

- 7 days for underside of slab up to 4.5 meter span

- 14 days for underside of slab, beams, arches above 4.5 meter up to 6 meter span.

- 21 days for underside of beams arches above 6 meter span and up to 9 meter span.

- 28 days for underside of beams arches above 9 meter span.

Defects Found In Shuttering/Form Work

- The supports of form work are not in plumb and are not cross braced.

- The ground supports of ballies are poor and therefore settle the form work.

- There is insufficient thickness of shuttering plates/planks unable

to bear lateral pressure imposed by wet concrete especially in columns.

- Shuttering plates are not cleaned and oiled or oiled with dirty oil.

- There are many insufficient and loose connections in centering and shuttering.

- The form work is removed before time. The work is not planned and designed properly.

- In case of beam shuttering proper provision for retaining side is not made. Hence the side of beam is not in proper line.

- The shuttering is poorly made with cracked and warped timber planks having lots of holes and knots.

- Through bolts for RCC walls form work for an underground tank is used. Later these holes made by bolts are not plugged.

- ‘Ballies’ are resting on bricks or brick pillars

- Ballies are not in one piece. Small ballies are used and these are

not properly jointed. Also no additional cross bracing is provided at

the joint.

- The supports under shuttering plates are not properly tight.

- The earth work under supports is not properly compacted before starting shuttering work.

- The bottom of ‘ballies’ are in wedge shape, not having proper base.

;

| | |

|

|

Questions (39) | |

4665

views | 4

answers | Last answer on 7/3/2020 10:42:19 PM. by JAI PRAKASH. Forum started by Manikandan | 12253

views | 2

answers | Last answer on 1/18/2013 3:22:15 PM. by gnyoganarasimhan. Forum started by selva | 2054

views | 1

answers | Last answer on 2/15/2017 1:14:19 PM. by S L Gupta (Civil Engg). Forum started by Rajkumar | |

| 5692

views | 2

answers | Last answer on 7/3/2020 10:36:16 PM. by SANJAY DUSANE. Forum started by sam_m400 | 3721

views | 2

answers | Last answer on 2/22/2021 2:25:37 AM. by SANJAY DUSANE. Forum started by Mohiuddin | 4012

views | 2

answers | Last answer on 7/28/2020 1:27:06 AM. by ringwang. Forum started by ringwang | 3838

views | 1

answers | Last answer on 7/3/2020 11:38:55 PM. by JAI PRAKASH. Forum started by R.Roy | 8421

views | 1

answers | Last answer on 7/3/2020 11:35:51 PM. by S L Gupta (Civil Engg). Forum started by Arun | 5214

views | 2

answers | Last answer on 2/2/2022 6:14:10 PM. by ringwang. Forum started by R.Roy | 3152

views | 6

answers | Last answer on 7/4/2020 3:06:52 AM. by JAI PRAKASH. Forum started by krishna pratap | 3304

views | 4

answers | Last answer on 7/3/2020 10:11:02 PM. by JAI PRAKASH. Forum started by manjula | 1979

views | 2

answers | Last answer on 7/3/2020 11:53:47 PM. by S L Gupta (Civil Engg). Forum started by AD | 3273

views | 3

answers | Last answer on 10/12/2014 8:43:10 PM. by SANJAY DUSANE. Forum started by Jahankumar | 5862

views | 1

answers | Last answer on 11/13/2016 12:55:24 AM. by S L Gupta (Civil Engg). Forum started by srikanth | 3784

views | 2

answers | Last answer on 7/25/2013 5:09:29 PM. by LAKWINDER. Forum started by paresh | 9197

views | 2

answers | Last answer on 11/10/2016 5:26:25 PM. by SANJAY DUSANE. Forum started by Vinod | 7836

views | 3

answers | Last answer on 3/18/2016 4:13:47 PM. by S L Gupta (Civil Engg). Forum started by Shabbir shaikh | 2559

views | 3

answers | Last answer on 10/15/2017 1:22:37 AM. by gautam kumar. Forum started by gautam kumar | 1367

views | 2

answers | Last answer on 7/28/2020 12:37:49 AM. by S L Gupta (Civil Engg). Forum started by vishal singh | 13

views | 0

answers | Last answer on 12/21/2024 12:29:49 AM. Forum started by rupeshji | 10

views | 0

answers | Last answer on 12/21/2024 12:29:40 AM. Forum started by rupeshji | 7

views | 0

answers | Last answer on 12/21/2024 12:29:32 AM. Forum started by rupeshji | 8

views | 0

answers | Last answer on 12/21/2024 12:29:24 AM. Forum started by rupeshji | 8

views | 0

answers | Last answer on 12/21/2024 12:29:18 AM. Forum started by rupeshji | 13

views | 0

answers | Last answer on 12/21/2024 12:29:12 AM. Forum started by rupeshji | 6

views | 0

answers | Last answer on 12/21/2024 12:29:05 AM. Forum started by rupeshji | 7

views | 0

answers | Last answer on 12/21/2024 12:28:58 AM. Forum started by rupeshji | 6

views | 0

answers | Last answer on 12/21/2024 12:28:51 AM. Forum started by rupeshji | 7

views | 0

answers | Last answer on 12/21/2024 12:28:44 AM. Forum started by rupeshji | 4

views | 0

answers | Last answer on 12/21/2024 12:28:38 AM. Forum started by rupeshji | 8

views | 0

answers | Last answer on 12/21/2024 12:28:31 AM. Forum started by rupeshji | 11

views | 0

answers | Last answer on 12/21/2024 12:28:24 AM. Forum started by rupeshji | 24

views | 0

answers | Last answer on 12/21/2024 12:28:18 AM. Forum started by rupeshji | 28

views | 0

answers | Last answer on 12/21/2024 12:28:10 AM. Forum started by rupeshji | 7

views | 0

answers | Last answer on 12/21/2024 12:28:03 AM. Forum started by rupeshji | 6

views | 0

answers | Last answer on 12/21/2024 12:27:56 AM. Forum started by rupeshji | 5

views | 0

answers | Last answer on 12/21/2024 12:27:22 AM. Forum started by rupeshji | 5

views | 0

answers | Last answer on 12/21/2024 12:27:16 AM. Forum started by rupeshji | 6

views | 0

answers | Last answer on 12/21/2024 12:27:08 AM. Forum started by rupeshji |

|

|

|

| Articles that might interest you! | | Centering and Shuttering / Form Work

Shuttering or Form work is most important part of any construction project. Steel, Wood or other likewise material is us | | Mild Steel Bars in Cement Concrete

Mild steel bars in reinforced concrete are one of the exceptional building materials. Reinforced concrete requires ver.. | | Tips for Laying RCC slab / roof

RCC slab laying is one of major step in any type of construction so it is mandatory to know all the points related to .. | | Septic Tank, It’s Principle and Guidelines

Septic tanks or soak pits are useful for disposal of waste in the areas or houses where public sewerage system is not .. | | Guidelines for Doors and Windows Opening in Walls

Doors or Windows opening in walls are skilled part of construction in home, work are or any other structure. It needs .. | | Dining Room Ceiling

Dining room ceiling designs can change the interior of your room. A white ceiling in your well furnished home looks du.. | | Types of Roofing

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way .. | | Flat Roof

Flat roof will be a better choice for which they want full use of building space. It appears flat with a slope for get.. | | Concrete Roofing- All time material

Concrete is an all time material for roofing. Simple flat roofs to sloped roofs, concrete roof tiles offered various s.. | | Rubber Roofing- Eco Friendly Option

If you are looking for leak-proof roofing material, choose rubber roofing. Rubber roof is an eco-friendly, durable and.. | | What are various types of glasses used in doors?

Types of glasses used in doors-Clear window glass, Plate glass, Prism glass, Quartz glass, Processed glass....... | | What are advantages and disadvantages of folding doors?

Advantages of folding doors- Easy to install,washable, durable, superior sound damping. Disadvantages-sensitive to har.. | | What are various designs available in wooden doors?

Designs available in Wooden doors..... | | What is standard size of internal folding doors?

Size, Thickness and Weight of Internal Folding Doors....... | | What affects the life of doors? What can we do to increase the life of the Wooden doors?

Tips to increase the life of Wooden doors.... | | What is the standard size of frame for Plastic/PVC doors?

Plastic Door frame size carrying one or two shutters...... | | What are various frames recommended for Plastic/PVC doors?

Frames for Plastic Doors.......... | | Which place is appropriate for sliding door?

Appropriate places for sliding doors-Bathrooms, Backyards, Commercial structures........... | | What are various frames recommended for glass doors?

Frames for Glass Doors-Wooden frames, Steel frames, Aluminium frames...... | | Which place is appropriate for folding doors?

Appropriate places for folding doors-Homes, Offices, Guest rooms, gives attaractive and stylish look........ | | What are the various accessories recommended for folding doors?

Accessories for folding doors- Door Handles, Door Fasteners,Door Viewers....... | | What affects the life of doors? What can we do to increase the life of the Plastic/PVC doors?

Tips to increase the life of Plastic doors.... |

|

|

|