Brick walls are probably the most common building elements in

construction of a house in India. These walls form basic units for

creating rooms that make up a house. The walls besides being space

dividers are also structural elements that transfer the load of the roof

to the ground. Brick walls are constructed on strip spread or raft

foundations that support the walls. The walls are constructed using

bricks and mortar. These can also be constructed with various structural

qualities and thicknesses.

Brickwork

Brick walls are constructed by joining bricks

with cement mortar in arrangements called English Bond, Flemish Bond or

Rat Trap Bond. These bonds give different external appearances to the

wall. All construction systems of brick walls are such devised that

vertical cross joints in any layers are staggered. The bricks thus

bonded form a solid mass that does not split when the wall is loaded

with live loads and dead loads.

Classification of Brick Work

The classification of brick work according to the quality of brick is following.

- First class brick work

- Second class brick work

- Third class brick work

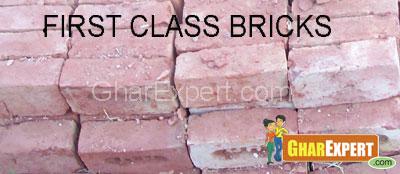

First Class Brick Work

First class brick

work is made by using first class bricks and cement mortar. This brick

work is used for load bearing walls. It is made in rich mortar in which

the cement and sand ratio is from 1:3 to 1: 6.

First class bricks are identified by their uniform color and a

ringing sound when struck. The bricks are equal in size and have even

edges and surfaces. These bricks do not chip and don’t have any cracks.

First class bricks do not absorb water more than 1/6 of their weight.

There is no salty residue when the bricks are dry. First class bricks

have a minimum crushing strength of 105.kg. Per sq. cm

Bricks of first class quality

Second Class Brick Work

Second

class bricks work is made by using second class bricks and cement

mortar. These bricks also have the property of first class bricks but

are not very regular or even in shape. These bricks should not be used

for load bearing walls for more than two storey buildings. Second class

bricks have minimum crushing strength 70.kg per sq. meter.

Second class quality of bricks

Third Class Brick Work

This type

of brick work is made by using third class bricks and cement mortar or

mud mortar. Third class brick work is not made in any Govt. work.

Generally this type of brick work is made for temporary work in private

sector.

Mortar

Mortar is a mix used to bind brick, stone etc to each other.

It

can thus be seen as a binding material that bonds bricks, stones to

make a wall or for cladding purpose. Normally cement mortar is used in

brickwork in present day construction though lime mortar can also be

used but it requires superior craftsmanship and is hence infrequently

used.

Cement Mortar

Cement mortar is a

mix of cement and sand with water. The cement is binding material which

requires sand as a filler material. This cement mortar mix in wet state

is plastic and binds two materials when it dries. Mortar is generally

defined as 1:2 or 1:3 or 1:7 etc. This means that one part of cement is

mixed with 2, 3 or 7 parts of sand.

Precaution for mixing cement mortar

The following steps should be taken carefully while mixing materials for cement mortar.

- The mix should be made on a dry, clean, flat surface.

- The mix should be as per specifications.

- The mix should be by volume.

- The quantity of water should be such that the mix can be easily

spread over bricks or applied on a vertical surface. Water more then

required quantity may spoil the mix and it can reduce the strength of

masonry.

- The mix should be used within half an hour of its preparation.

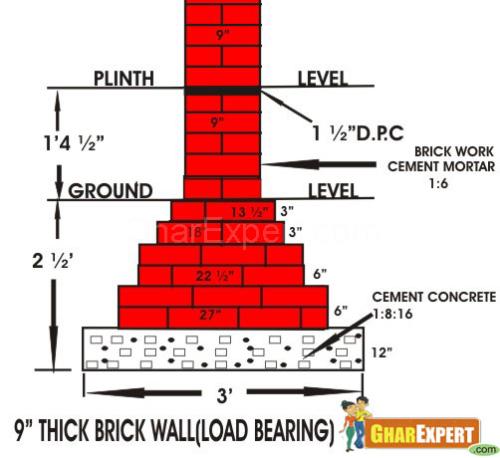

Brick Wall Foundations

Brick wall foundations are normally made as strip foundations.

These

are continuous along the length of wall and hence called as strip

foundations. These form structural components of construction system by

which the load of whole building is transferred to the ground.

Foundations

are made in dug out trenches so that a hard stable surface on which the

building is supported can be obtained because the top surface of the

ground normally does not have load bearing capacity to take the load of

the building. The other reason is that foundations can by this method be

hidden from view. The architect needs to provide a foundation plan that

indicates exactly where the foundation trenches are to be dug.

The foundation trenches are dug after being marked on center line

principle on the site according to architect’s drawings. The size of

trench varies with the thickness of walls and the load bearing capacity

of the soil. The base of dug trench is rammed to solidify the surface.

On rammed surface a layer of cement concrete is laid. This is normally 6

to 8 inches thick. This base concrete layer needs to be cured for it

attains its expected strength. Base concrete layers or courses of bricks

are laid to create a stepped base that would help in distributing the

load over a larger surface of the foundation.

Precautions during construction of brick wall foundations

- The marking of foundations must be absolutely accurate as the location of walls depends on these markings.

- The trenches should not be dug in rainy season. The bricks, mortar mix and cement concrete mix should be as per specifications.

- The width and depth of the trenches depends on loading and soil

conditions. As the foundation is an expanded base to distribute the load

coming on it over a large area on ground. The width of the wall

foundation depends on whether the wall is a load bearing wall, a non

load bearing wall, a partition wall or a toe wall.

Load Bearing Walls

The walls that support beams and roof slabs.

- These walls take the load of super structure and transmit it to the ground through foundation.

- These can also serve the purpose of dividing the space into required rooms etc.

- These are also accommodating door and windows where required.

- These are of 9” or more thickness.

- Such walls are made in first class bricks and rich mortar.

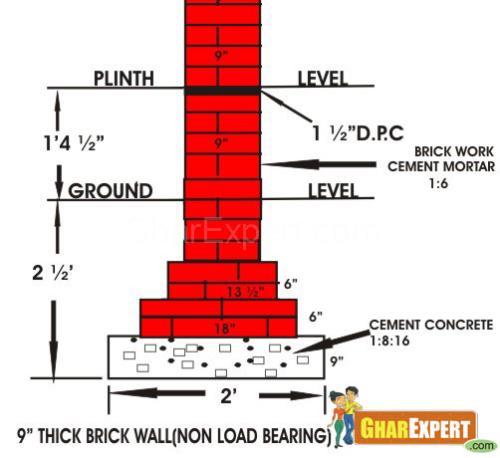

Non Load Bearing Walls

- These walls serve the purpose of dividing the space into required rooms etc.

- These are also accommodating door and windows where required.

- These can be made into thin sections to save the space.

- Non load bearing walls are only partition having no load of super

structure so these can be easily changed whenever required to change the

space of the room.

- These walls are made 3 inches, 4.5 inches and 9 inches thick as per the requirement of the site.

Super Structure:

The word super structure used in construction work means/denotes following.

- Brick work from DPC level to the roof level/slab level.

- If columns provided in drawings then RCC columns to be laid.

- Rain water pipe is to be embedded in walls.

- Fixing doors, windows and ventilators frames in walls.

- RCC (Reinforced Beam & slab for roof) including M S Steel bars according to the designs.

- Tile terracing lay with brick tiles on the top of the roof slab.

- Fixing doors and windows shutters.

- Fixing cupboard in the rooms and Kitchen etc.

- Fixing iron grills for safety of the house.

- Providing cement plaster on ceiling and walls.

- Laying floors including base coat.

;