Essential requirement to human existence is a HOME next only to food and clothing. A breakthrough for application of sustainable and cost effective technologies for better housing in rural and urban areas is an urgent need considering spiraling construction costs.

There is a need for the adoption of strong, durable, environment friendly, ecologically appropriate, energy efficient and yet cost effective materials and appropriate technologies in construction.

Here are some innovative options which can contribute in reduction of cost and at the same time offer solutions which are aesthetic and acceptable for the varying regions and socio- economic profiles of our country.

Walling:-

a)Stabilized compressed earth blocks are made of mud stabilized with 5% cement/lime etc. and compacted in block making machine with no burning. A good walling material as burnt bricks and is economical, stronger, energy saving and simple to manufacture. The soil to be used for the blocks should have the requisite component of clay and silt and sand etc. soil stabilized hollow and interlocking blocks can provide better thermal insulation.

b) Fly ash gypsum stabilized mud blocks are much stronger with less water absorption and cheaper than cement stabilized blocks. With 5 to 10% flyash- G, 30% saving in cement could be achieved in addition to utilization of the waste product like flyash.

c) Flyash- lime gypsum products manufactured by blending flyash lime and calcined gypsum for making a useful product named Fal-G , and can be used a cementateous material for mortar/plaster and for masonry blocks of any desired strength. It can also be used for road pavements and plain concrete in the form of Fal-G concrete.

d) Clay red mud burnt bricks produced from alumina red mud or bauxite, an industrial waste of aluminium producing plants in combination with clay. Posses all the physical properties of normal clay bricks and solves the problem of disposal of the waste product and environmental pollution. In addition, they have good architectural value as facing bricks due to their pleasing hues of color.

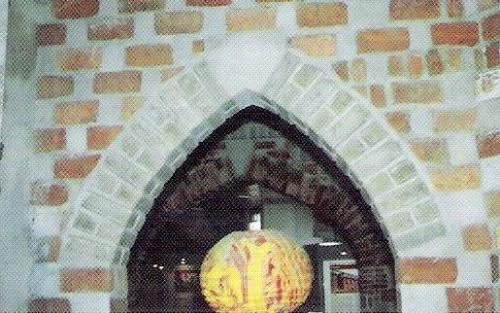

e)Precast stone blocks of larger size than normal bricks are manufactured by using waste stone pieces of various sizes with lean cement concrete and enable a rationalized use of natural locally available materials. Shaping stones in this manner, enables speedy construction saves on cement, reduces thickness of stone walls and effects overall saving by eliminating plasters on internal/external wall surfaces.

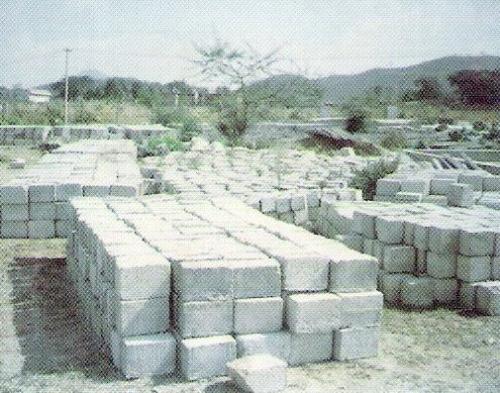

f) Precast concrete blocks made to similar dimension of stone blocks without large size stone pieces, but using coarse and fine graded cement. They have excellent properties comparable to other masonry blocks, are cheaper and facilitate speedy construction and especially suitable where quality clay for bricks making is not available.

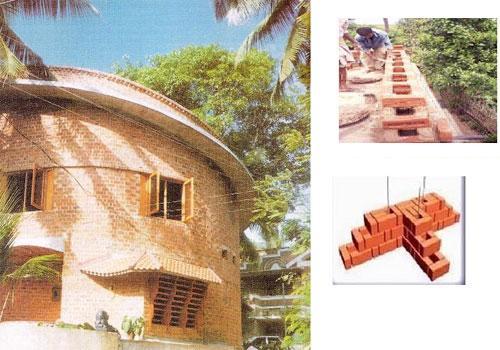

g) Rat trap bond is an altenate brick bonding system for English and Flemish bond. This is economical, strong and aesthetic. 25% of the total number of bricks and 40% of mortar can be saved by using rat trap bond. It is simple to build and has better insulating properties.

ROOFS:-

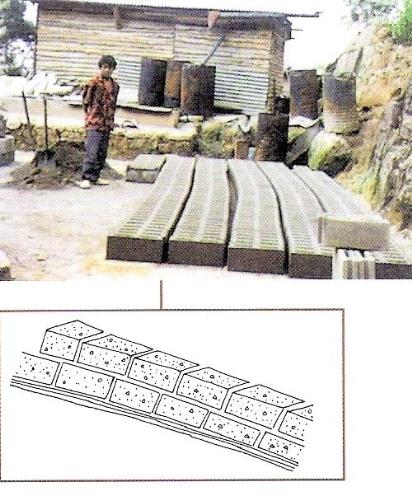

a)Funicular shells over edge beams provide a simple and attractive alternative to RCC construction for small to medium spans. These can be used to span square, rectangular or even tri angular and non orthogonal spaces and consist of thin shell of concrete, brick, stones, tiles supported on edge beams. These are cost effective as the required quantity of steel and cement is much less and can be precast avoiding costly shuttering.

b)Filler slabs are normal RCC slabs where bottom half (tension) concrete portions are replaced by filler materials such as bricks, tiles, cellular concrete blocks, etc. these filler materials are so placed as not to compromise structural strength, result in replacing unwanted and non functional tension concrete, thus resulting in economy. These are safe, sound and provide aesthetically pleasing patterns ceiling and also need no plaster.