All channels  ArchiStud - where creativity takes shape ArchiStud - where creativity takes shape  Filler Slabs Filler Slabs |

|

| ArchiStud - where creativity takes shape

How a life of an architecture student is different in perceiving the world. | |

| |

|

|

|

| Filler Slabs | |

|

| | By:Gunjan Utraja - On Monday, April 13,2009 - 153570 View(s) - 41 Comment(s) |

| |

FILLER SLAB

The Concept doesn't come in the way of structural strength and gets things done in an economical way

There is a lot of difference between cheap construction practices and cost effective ones. While taking up construction, most fail to appreciate the difference and end up spending quite a bit of their money. This against a possibility of cost - effective options that while ensuring good and efficient construction also leaves you with a substantial saving.

Expert calculations suggest that cost-effective construction will have you saving at least 25 per cent of the cost that otherwise would have into your home. The quest for cost-effective, innovative and environment-friendly housing has focused on the appropriate use of locally available materials, skill and technology without compromising on the quality and life of the structure.

Filler slabs are one such cost - effective roofing system which is based on the concrete portions and instead placing filler material there. The material used as a replacement includes bricks, tiles, cellular concrete blocks.

Reinforced concrete

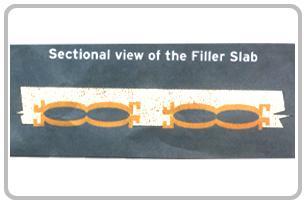

The filler slab is based on the principle that for roofs which are simply supported, the upper part of the slab is subjected to compressive forces and the lower part of the slab experience tensile forces. Concrete is very good in withstanding compressive forces and steel bears the load due to tensile forces. Thus the lower tensile region of the slab does not need any concrete except for holding the steel reinforcements together.

Therefore in a conventional RCC slab lot of concrete is wasted and it needs extra reinforcement due to added load of the concrete which can otherwise be replaced by low-cost and light weight filler materials, which will reduce the dead weight as well as the cost of the slab to 25% (as 40% less steel is used and 30% less concrete).

The filler slabs also result in fewer loads getting transferred to the load-bearing walls and the foundations. The air gap in between the tiles makes it a good heat insulator and the ceiling looks attractive as well.

Filler slab as projection, creating an interesting articulation.

The mechanism

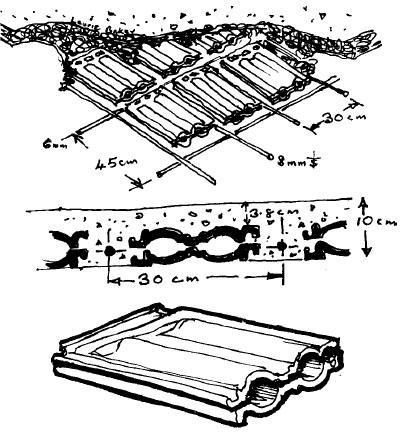

The filler slab is a mechanism to replace the concrete in the tension zone. The filler material, thus, is not a structural part of the slab. By reducing the quantity and weight of material, the roof become less expensive, yet retains the strength of the conventional slab. The most popular filler material is the roofing tile. Mangalore tiles are placed between steel ribs and concrete is poured into the gap to make a filler slab. The structure requires less steel and cement and it is also a good heat insulator.

Strength of filler slabs.

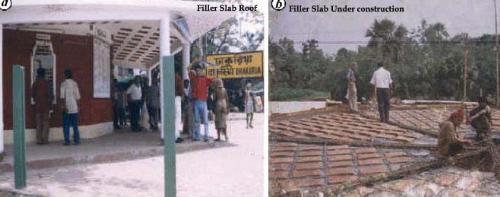

Conventional tests by different institutions and laboratories has proved the load bearing capacity of filler slab and found it no less in performance from the conventional R.C.C. slab. Since filler roof tiles are firmly bonded to and covered by concrete, it does not collapse under the impact of say, a coconut falling on the roof.

Leak proofing filler slabs.

With proper supervision and workmanship, leaks can be avoided. The chance of a leak in a filler slab is much the same as the conventional R.C.C.slab.

Saving on cost

The savings on cost can be from 15 per cent to 25 per cent. But designing a filler slab requires a structural engineer to determine the spacing between the reinforcement bars.

Other favored filler materials include clay pots, stabilized mud blocks, brick or brick panel, broken pieces of cement blocks and even coconut shells. The quantity of concrete in the tension zone of the slab that can be replaced by a filler material depends upon the shape of the filler material and the thickness of the solid slab.

Thermal insulation

The air pocket formed by the contours of the tiles makes an excellent thermal insulation layer. The design integrity of a filler slab involves careful planning taking into account the negative zones and reinforcement areas.

Patterned ceilings

Filler slabs provide aesthetically pleasing patterned ceilings. In most houses, the filler material is left open without plastering to form aesthetic design symmetry but some residents prefer to cover the space with Plaster of Paris coating.

Different patterns in ceiling can be attained

Thus the filler slab as the roof has the following advantages:

• Consumes less concrete and steel due to reduced weight of slab by the introduction of a less heavy, low cost filler material like two layers of burnt clay tiles. Slab thickness minimum 112.5 mm.

• Enhances thermal comfort inside the building due to heat-resistant qualities of filler materials and the gap between two burnt clay tiles.

• Makes saving on cost of this slab compared to the traditional slab by about 23%.

• Reduces use of concrete and saves cement and steel by about 40%.

Do not allow the architect, the engineer, and the building contractor to be dictators. You tell them what you want!

Contact Gharexpert.com

|

| |

|

| Did you enjoy this post? Please share it! |  |  |  |  |  |  |  |  |  |  |  |  |  |  |  |  |  |

|

|

| 40 Comment(s) |

|

|

|

| By satya : On Sunday, January 23,2011 Normally a mason will put iron bars every six inch. If you use filler slab technique, can we increase the spacing to nine inch? or one feet?( 12 inch) for spans 15x15 ft |

| |

|

| By R. PANDEY : On Wednesday, August 11,2010 Filler slabs provide comfort against heat as well as econmy without compromising the required strength.a greate national saving. |

| |

|

| By Manimaran : On Sunday, December 28,2008 I heard that normally a mason will put iron bars every six inch. If you use filler slab technique, can we increase the spacing to nine inch? or one feet?( 12 inch) |

| |

|

| By Premie : On Wednesday, October 15,2008 the info was just wat i was lookin for.... thanks alot! |

| |

|

| By pradaush : On Saturday, September 20,2008 In Kerala, the cost of the so called fillers mangalore tile and bricks will be almost same as that of the concrete. Some alternative has to be worked out. |

| |

|

| By narendra : On Wednesday, September 3,2008 i have construct duplex house bunglow and get u r way ideas false celling types designed pattern need. this siter really useful. |

| |

|

| By Himanshu Patel : On Wednesday, July 2,2008 thanks. done a gud job. |

| |

|

| By meera mohammad : On Thursday, June 26,2008 obtaining latest methids of building construction |

| |

|

| By stockdigger : On Tuesday, June 10,2008 Excellent. Three cheers. Excellent illustration. |

| |

|

| By Suresh Kumar : On Sunday, June 8,2008 Use ful Information.Tks |

| |

|

|

<<  1234 1234 |

|

|

| Add Comments/Feedback |

|

|

| *Your name | | *Email address | |

| |

| *Comments/Feedback | (Max 4000 characters.) |

|

|

|

|