How to level concrete sub floor before installing wooden block flooring?

The recommended method for leveling of concrete in wooden block flooring is as follows:

- Termite treatment

When earth work under floor is completed, then termite treatment is done as follows

- Dig few holes in the earth before laying the floor. Fill them with anti-termite chemical.

- Also, fill chemical at the junction of walls and floors.

- Dig 300 mm deep holes at the external perimeter of the building and fill them with chemical as a barrier.

- Make holes into the earth and fill them with chemicals to treat the soil under plinth protection and around pipe.

- Treat expansion of joints at ground level with anti termite chemical treatment.

- Use anti termite chemical to treat ‘chowkhats’ or door frames before fixing them into the building.

- Base Concrete

Before laying floor, the base coat and concreting should be laid in the following manner:

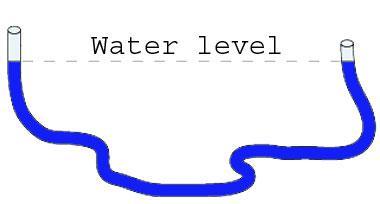

- Floor Levels should be marked on the walls and pillars with the help of water level.

Water level tool

(This picture is contributed by Rashi)

- The earth under floor should dressed according to floor levels marked on the walls and pillars

- The earth should be properly compacted with the help of watering and ramming.

- Do Sand piling to ensure proper compaction of the earth under floor.

- Lay 100 mm thick fine sand on compacted earth.

- After laying fine sand, lay 100 mm thick cement concrete in the ratio 1:8:16 with the help of mechanical mixer.

- It must be ensured that the base coat laid is fully compacted by hand rammers or with surface vibrator.

- Leveling Concrete

- A layer of leveling concrete should be at least 25 mm thick.

- Cement concrete should be in the ratio of 1:2:4 i.e. 1part of cement, 2parts of fine aggregate and 4 parts of coarse aggregate.

- It should be laid in proper slope and in level with the help of straight edge and trowel.

- It should be perfectly compacted by hand compaction with wooden thappy.

- The surface should be finished with wooden float to give sand paper finish, plane and true to level.

- While laying and leveling concrete, ensure the finish level of the concrete. It should be lower than the proposed finish level of the flooring by the specified thickness of the wooden block plush minimum of 1.5 mm.

- It should be cured for 7 days. After curing the surface allowed to dry thoroughly before paving the wooden blocks.

A beautiful, elegant and sophisticated option of flooring adds to the value of your home. Oak flooring is such a choice that complements to the decor and design of your home. It is hygienic, hard wearing, and easy to clean. This article tells you about manufacturing, installation and benefits of oak flooring.

A beautiful, elegant and sophisticated option of flooring adds to the value of your home. Oak flooring is such a choice that complements to the decor and design of your home. It is hygienic, hard wearing, and easy to clean. This article tells you about manufacturing, installation and benefits of oak flooring.

Do you want to add some spice to your home with amazing patterns of wooden flooring? Its' carved designs can keep pace with latest lifestyles. These designs and styles have always been known for their aesthetic craftsmanship.

Do you want to add some spice to your home with amazing patterns of wooden flooring? Its' carved designs can keep pace with latest lifestyles. These designs and styles have always been known for their aesthetic craftsmanship.

Wooden board flooring buying guide to help you choose the best wooden board.

Ever wondered how to start a diagonal hardwood floor installation? This article provides useful tips for giving your flo

Installation Precautions are compulsory to make wooden flooring long lasting. If You do not follow these precautions, you will have to bear a great loss in your wooden floors.

When you feel that the finishing of the floor is out of fashion or you are getting bore of it, refinish your old hardwoo

Two types of Wooden flooring:1. Wooden Boards flooring, 2. Wooden Block flooring

The screws should be countersunk.Iron screws shall be of the slotted countersunk head type.

Boards of hardwood or softwood are of good quality and free of knots.The usual thickness of the boards is 19 mm or 25 mm.

Raw materials for Wooden board flooring-Wooden boards, Wooden planks such as Deodar, Pine, Galvanized metal floor clips

Timber can be seasoned by providing a long drying time

The leveling layer of concrete shall be cement concrete 1:2:4 (1 cement,2 coarse sand,4 stone aggregate 10 mm nominal size by volume

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Different steel bars are recommended for their relative tensile stresses.Steel bars are major components of construction.Here is what you need to know about steel bars (Sariya).

Different steel bars are recommended for their relative tensile stresses.Steel bars are major components of construction.Here is what you need to know about steel bars (Sariya).

Brahmasthan is a powerful zone of the house. It should have open space for flow of energy in the house. The positive energy is very useful for living beings of the occupants of the house.

Brahmasthan is a powerful zone of the house. It should have open space for flow of energy in the house. The positive energy is very useful for living beings of the occupants of the house.

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Wooden flooring on stairs and flooring

Living Room LCD unit, Furniture, wooden Flooring, Carpet, Floor Lamp

tile floor for open kitchen and wooden floor for dining area

wooden flooring for bedroom with wooden batons on ceiling

concrete roof slab cutting by core cutting machine and lifting by chain block-9841125344

industrial concrete floor cutting work

industrial concrete floor cutting work

Wooden floor and wooden wall cladding in dining room

Concrete design for flooring

Concrete Basement Flooring

Guidelines for Laying Cement Concrete Floor

Kota stone Flooring in exterior flooring

2BHK floor plan for first floor

3D House Floor plan Designs, ideas, Images By Yantram 3d floor plan Vegas, USA

Floorplan of ground floor & first floor

Ground floor,1st,2nd 3rd and 4th floor plans

First Floor map of 6 Floor building

water level tool help in marking level lines for ceiling and flooring etc.

Elevation design showing ground floor first floor and boundary wall

Cellular Light Weight Concrete (CLC) Foam Concrete Plant Manufacturer

floor mate

Bathroom Planning, Ceiling, Lighting, Vanity, Flooring, Bath tub and Interior

Drawers wooden tall unit

Wooden Interior door design

Decorative Lights in Luxrious Bedroom

modren bed room

Exterior Wooden Door

Bathroom Interior, Flooring, Walls, Basin , Walls, Doors, Mirrors

Kitchen

Vinyl Flooring Design

Wooden kitchen cabinets with bar counter

Wooden

Dining room Wooden Furniture

Living room Ceiling, Lighting, LCD unit, Wall Unit, Furniture and Flooring

Perimeter Border Flooring

Wooden center table design

Contemporary living room

layout plan

FLOORING

Kitchen Interior with Brown Concept

red colored tiles on floor in Dining room

Wooden entrance door design with arch

Kids room interior, wardrobe, flooring, ceiling, furniture design

Living Room Ceiling and Flooring

kitchen flooring

Hardwood flooring with steel strips for open kitchen and living room

Bed and Bath

Flooring 3

Patio flooring

Copyright 2007-

GharExpert.com All rights reserved.