Water Proofing Treatment for Basement

(This article is specifically designed for Indian continent)

A dry basement is a fun place to have. Usually home owners do not care for proper design of the basement at the time of consutruction and face tremendous problems later on. If care is taken initially, a lot of problems can be avoided.

These methods can be applied for water proofing of basement during construction.

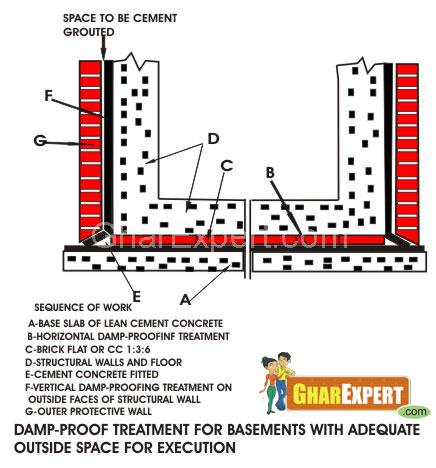

- Basement where adequate space is available for excavation.

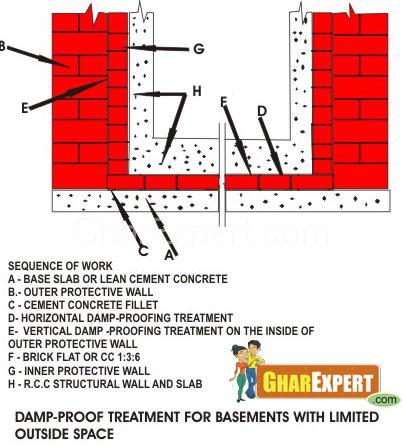

- Basement where limited space is available for excavation

Basement where adequate space is available for excavation

The excavation of ground for basement is carried out in such a manner that working space of at least 60 cm is available around external walls. If water level is high, the excavated area should be kept dry by continuous pumping.

The following operations are executed in water proofing of basement.

1) On dry and leveled ground 75 to 100 mm thick lean concrete is laid to serve as a leveling course for water proofing.

2) The bitumen based primer is applied with brush on entire area at 0.24 to 0.30 liter per sq. meter after cleaning the surface.

3) Bitumen compound polyester membrane is fixed in hot bitumen of grade 85/25 at the rate of 1.5 kg. Per square meter. This layer should be protected by construction of flat brick flooring.

4) After construction of structural slab and walls, water proofing treatment on external face which is in contact with earth is done.

5) After the surface is cleaned, bitumen primer is applied.

6) Self adhesive S B S rubber bitumen membrane with high density polyethylene film is applied on vertical walls.

7) Before back filling the soil an outer protective wall leaving a space about 100 mm around should be made and the space should be grouted subsequently.

Basement where limited space is available for excavation

The following operations are executed in water proofing of basement where space for excavation around basement is limited.

1) The base slab of lean concrete is laid followed by construction of external protective wall. Its internal face is rough plastered. Horizontal damp proofing treatment is carried out.

2) In the same manner as described in above process vertical damp proofing treatment is applied on inside plastered surface of the protective wall.

3) The treatment should be continuous on the wall and the floor.

4) For vertical damp proofing continuous with horizontal a fillet 75 mm ratios of 1:4 cement mortars should be provided at the junction of the slab and outer protective wall.

5) The horizontal and vertical damp proofing is protected against damage during subsequent operations.

6) Flat brick flooring and an inner protective wall are constructed.

7) The space of 100 mm left between vertical damp roofing treatment and internal protective wall is grouted after laying damp proofing membranes.

8) Thickness and reinforcement of RCC structural slab and walls are designed according to depth.

Basement walls always needs special care because of outside pressure of soil. Read about What care should be taken for designing and constructing the basement walls.

Basement walls always needs special care because of outside pressure of soil. Read about What care should be taken for designing and constructing the basement walls.

Basement Flooring need extra care because of moist and dampness conditions. Read details about basement flooring options and precautions you need to take while choosing flooring for basement.

Basement Flooring need extra care because of moist and dampness conditions. Read details about basement flooring options and precautions you need to take while choosing flooring for basement.

Finish your Basement Ceiling with great ideas from GharExpert ceiling design gallery. Make your basement more inviting with the right choice of ceiling design. Get new style and defination to your basement.

Finish your Basement Ceiling with great ideas from GharExpert ceiling design gallery. Make your basement more inviting with the right choice of ceiling design. Get new style and defination to your basement.

Do you want to make your home a multi-purpose location? Design a basement to serve various purposes like gym, home office, living room etc. Before you begin to design interiors of the basement of your house, you need to know basement interior design ideas and various problems of basement design.

Do you want to make your home a multi-purpose location? Design a basement to serve various purposes like gym, home office, living room etc. Before you begin to design interiors of the basement of your house, you need to know basement interior design ideas and various problems of basement design.

Basement interior design can fulfill your dreams of enjoying more space. You can highlight dark space of basement in effective ways. Read this article to know more 'Basement Interior Design’ and 'Basement Design Principles' .

Basement interior design can fulfill your dreams of enjoying more space. You can highlight dark space of basement in effective ways. Read this article to know more 'Basement Interior Design’ and 'Basement Design Principles' .

Construction of basement and multi storey building is the need of the hour as there is less availability of land and rates of the land are very high. We get additional usable space by constructing either basement or upper floor.

Construction of basement and multi storey building is the need of the hour as there is less availability of land and rates of the land are very high. We get additional usable space by constructing either basement or upper floor.

Basement serves the purpose of extra space and provides strong base for upper storey.

Basement serves the purpose of extra space and provides strong base for upper storey.

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Different steel bars are recommended for their relative tensile stresses.Steel bars are major components of construction.Here is what you need to know about steel bars (Sariya).

Different steel bars are recommended for their relative tensile stresses.Steel bars are major components of construction.Here is what you need to know about steel bars (Sariya).

Brahmasthan is a powerful zone of the house. It should have open space for flow of energy in the house. The positive energy is very useful for living beings of the occupants of the house.

Brahmasthan is a powerful zone of the house. It should have open space for flow of energy in the house. The positive energy is very useful for living beings of the occupants of the house.

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Are you remodeling your bathroom? Bathroom shower doors make your bathroom a style icon. Read the following article that will help you select the bathroom shower door that will exactly suit your bathroom.

Are you remodeling your bathroom? Bathroom shower doors make your bathroom a style icon. Read the following article that will help you select the bathroom shower door that will exactly suit your bathroom.

Living room or Drawing room should be located in east or north direction. The ideal location of a living room depends on plot facing.

Living room or Drawing room should be located in east or north direction. The ideal location of a living room depends on plot facing.

Damp Proofing With Limited Space

Shock proof earthing

wall treatment

Cool wall treatment

wall treatment

False Ceiling Treatment for Flat Roof

False Ceiling Treatment for Pitched Roof

Drawing Room Window Treatment

Ultra Modern Bedroom with Wall Treatment

window treatment

wall treatment

wall treatment

wall treatment

wall treatment

pit for basement

Application sketch - roof water proofing

column treatment

Door Frame Treatment

Mandana Stone (Acid proof)

Residential house.. Laying Base Concrete with Termite proofing

column treatment

window treatment

wall treatment

wall treatment

Cool wall treatment

wall treatment

False Ceiling Treatment for Flat Roof

False Ceiling Treatment for Pitched Roof

Drawing Room Window Treatment

Gym in basement

Excavation for basement

basement

basement excavation

Basement and Underground

Basement

Application sketch - roof water proofing

Damp Proofing With Limited Space

Shock proof earthing

Ultra Modern Bedroom with Wall Treatment

Basement Construction

PVC Water Stopper

Library in Basement

Furnished Living Room in Basement

Furnished Basement Picture

Concrete Basement Flooring

Rain Water Pipe

Under water world kids room paint ideas

Use of bad quality water in construction cause this.

POP Design for Basement Ceiling

Location of Water Sump

Modern Bedroom with Stairs

Water seal

Basement Flooring Ideas

Basement, Ground and first floor planning

under water bedroom

Home Gym in Basement

Basement Bar Ceiling

little swimming pool and water fall

Basement RCC Wall

wall treatment

water falls

wall treatment

Painting- The Sleeping Beauty