Brick Work

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement. It is done in different parts of the building/structure according to the requirement/ architectural design of the buildings as given below:-

Brick work in foundation

Brick work in foundation is done to transfer the load of super structure to the ground. The width of the brick work in foundation is taken according to the load coming on it. The load of super structure is divided into various steps of brick works in foundation below plinth level. Care may be taken that all steps should accommodate in the ground. The foundation should be made according to the drawing and design.

Brick work in super structure

Brick work above plinth level is called brick work in super structure. Brick work in super structure transfer the load of RCC beam and slabs to the foundation of the walls. Doors, windows and ventilators are accommodated in this part of brick work. This part of the building is used to divide the space into required room etc. Outer walls may be used for ornamental design of the building.

Brick work in parapet

Brick wall constructed on roof slab on terrace is called parapet walls. Parapet walls are necessary to protect persons using terrace from falling. It is also necessary to construct parapet wall for the safety of the joints of outer wall and RCC slab. It also adds to the beauty of the building.

Parapet of a building

(This Picture is Contributed by "Ahmed")

Brick work in partition walls/half brick walls

The partition walls are required to divide the space according to the design. The thickness of these walls is 4.5 inches. Due to thin section of the wall the usable space is increased. As there is no load on these walls so they can be changed easily when any additional/alternation is required in the building. The cost of thin walls is less hence they are economical.

Brick tiles masonry

For enhancing the beauty of buildings, the exterior/exposed surface of wall is constructed with the brick tiles according to the architectural drawings. For making this design brick tile masonry is done on required walls which is shown in the elevation of drawings.

Brick jali

Brick Jali is constructed to enhance the beauty of the building. In veranda brick Jali gives extra air and light and protects from rain up to some extant. It saves the cost of the walls.

Brick Jali

This Picture is Contributed by "Ashish Batra")

(To read a post on "Brick Jali" by Ashish Batra visit http://www.gharexpert.com/a/ashishbatra/1687/BRICK-JALI-0.aspx )

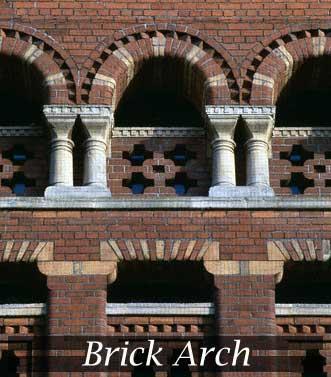

Brick work in arch

Arch is constructed to beautify the building. These are provided in openings to save the cost of RCC lintel.

(This Picture is Contributed by "Ahmed")

Brick work according to cement mortar ratio

1. First class brick work in cement sand mortar 1:4

Brick walls constructed with cement sand mortar 1:4 ratio means 1 part of cement and 4 parts of sand. This mortar is of high strength and is recommended for following construction works.

- Multi storey buildings

- Heavy weight /load bearing walls

- In earth quake zones

- Brick pillars

- Where there is more vibration due to heavy traffic or factory.

- Boundary wall, courtyard wall parapet wall and other free end walls

- Partition or 4.5 inch thick walls

- Brick works used for drainage

2. First Class Brick Work in cement sand mortar 1:6

Brick walls constructed with cement sand mortar 1:6 ratio means 1 part of cement and 6 parts of sand. This mortar is of medium strength and is recommended for following construction works.

- Three storey buildings

- Load bearing walls

- Heavy and frequent rainy zones

- Foundation of multi storey buildings

3. First Class Brick Work 1:7

Brick walls constructed with cement sand mortar in the ratio of 1:7 means 1 part of cement and 7 parts of sand. This mortar is low in strength and is recommended for following works.

- Toe walls

- Single storey buildings

- Temporary structures

- Light weight walls having no load of beams etc.

Note: Mortar richer than 1:3 are not used in masonry because of high shrinkage and no appreciable gain in strength of masonry although mortar strength itself may increase.

Common defects in brick work and cement mortar

- Raw materials like brick, sand, cement and water are of sub standard quality without qualifying any test.

- Bricks are not soaked in water properly.

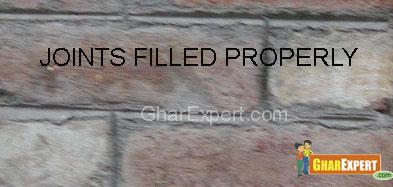

- The joints in brick works are thicker, unfilled properly.

- Raking of mortar is not done when the mortar is green.

- Bricks bats are used in masonry work.

- Mortar is not mixed properly on platform.

- There is improper mixing of cement mortar

- There is excessive water content in mortar

- Brick work is not in plumb, level and straight line.

- Mortar is not according to the structural requirements.

- There are gaps between door/window frame and masonry.

- The holes of scaffolding are not filled in with mortar properly.

- Vertical joints in brick work are hollow.

- There is high suction of brick and less water retention of mortar

- There are uneven joints in brick works

- There are voids in vertical joints

- There are disturbances of brick works just after the layout

- Over thick joints reducing the strength of brick work.

Precautions in brick work

- The length and width of the walls should be according to the drawings.

- The quality of bricks should be good having required strength and should not show any efflorescence (salt on face).

- The sand should not have fine grains and be free from silt etc. The sand used for brick mortar should be of required FM (Coarser) with no silt.

- The mixing of mortar should be proper with required quantity of water. It should not be dry or liquid.

- The opening of doors and windows should be left simultaneously, not by dismantling.

- During the brick work in a building the Rain water and Sanitary pipes should be fixed during the brick work other wise the brick work would have to be dismantled to fix the pipes.

- The bricks are soaked in water before use otherwise these will absorb water from the mortar and the bonding will be weak

- The water should penetrate to the core of the brick but the brick should be skin dry i.e. from outside when it’s used in actual.

- The frog or depression side of the brick should be upwards.

- Minimum number of bats is used.

- Bricks are absolutely aligned horizontally and in a straight line. This can be checked by a stretched string across the face.

- The bricks are vertically aligned which can be checked with a plumb bob.

- The courses or layers of bricks are level. This can be checked with a spirit level.

- The thickness of joints is not more than 1 cm.

- The joints should be filled with mortar fully without any gaps.

- The joints are pushed inside when cement mortar is still wet so that later plastering can be done effectively.

- Brick work should be kept wet for seven days so that the mortar may gain its full strength.

- There are no continuous vertical joints

- Bricks, sand and cement used in brick work should be according to their specifications

Tools recommended for brick work

- Wooden setting out square

- Spirit level

- Water level

- Boning rod

- Plumb rule

- Laying trowel

- Brick hammer

- Lump hammer and bolster chisel.

- Double end comb hammer

- Straight edge

- Brick work gauge rod

- Checking the accuracy of spirit plumb level

Strong brick walls are a symbol of strong building. Whole construction process somewhere depends on it. So here is a brief detail of what you need to keep in mind while brick wall construction is going on.

Strong brick walls are a symbol of strong building. Whole construction process somewhere depends on it. So here is a brief detail of what you need to keep in mind while brick wall construction is going on.

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

Kota stone flooring is a subtle blend of grandeur and luxury giving the interior and exterior a gorgeous look.......

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

To get maximum ventilation and natural light in your house, make sure the building is properly oriented. Orientation of building saves energy and provides comfortable living as well. This article tells you about various factors and benefits of building orientation.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

Preview some of the most impressive pictures of kitchen from GharExpert Gallery.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

A solid roof on building is very important for everybody living in the house. The roof should be constructed in a way that assures you great safety. Here are given details about different types of roofing.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Frames of doors and windows are most important parts of your doors and windows. They are available in different size, height, width and shapes. Frames hold locks and hinges and support door and windows to shut and open easily. Here is what you need to know about different doors and windows frames.

Different steel bars are recommended for their relative tensile stresses.Steel bars are major components of construction.Here is what you need to know about steel bars (Sariya).

Different steel bars are recommended for their relative tensile stresses.Steel bars are major components of construction.Here is what you need to know about steel bars (Sariya).

Brahmasthan is a powerful zone of the house. It should have open space for flow of energy in the house. The positive energy is very useful for living beings of the occupants of the house.

Brahmasthan is a powerful zone of the house. It should have open space for flow of energy in the house. The positive energy is very useful for living beings of the occupants of the house.

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Brick work is an important part of construction work done with the help of bricks and cement mortar. It is done with different quality of bricks with different ratios of cement mortar according to the requirement.

Are you remodeling your bathroom? Bathroom shower doors make your bathroom a style icon. Read the following article that will help you select the bathroom shower door that will exactly suit your bathroom.

Are you remodeling your bathroom? Bathroom shower doors make your bathroom a style icon. Read the following article that will help you select the bathroom shower door that will exactly suit your bathroom.

Living room or Drawing room should be located in east or north direction. The ideal location of a living room depends on plot facing.

Living room or Drawing room should be located in east or north direction. The ideal location of a living room depends on plot facing.

Cellular Light weight Concrete (CLC) bricks

duplex 30' front brick cladding and Iron steel railing on first floor

brick

glass bricks in ceiling above the lobby stairs

Exposed Brick

Compact living room 3 D design with brick wall cladding

First Class Bricks

POP Ceilling, Pillar work at entrance, Stone work on wall Professionalism

Brick Work for construction

Nice Brick Work

brick work and truss

Brick Work

Brick Work

Brick Work On DPC

Brick works..

Brick Work in Foundation

Cement Concrete and Brick Work in Foundation of Wall

SECON CLASS BRICK WORK

FIRST CLASS BRICK WORK

First class brick work

Brick Work in Foundation

Brick Work

Brick Work On DPC

Brick Work

brick work and truss

Brick works..

brick style

Brick Light

Ground Work

Thick Brick Wall ( load Bearing)

wooden Wardrobe work

Wardrobe in veneer work'

Veenered panelling in brick pattern

bricks

Painted-white brick

brick

Cement Concrete and Brick Work in Foundation of Wall

SECON CLASS BRICK WORK

FIRST CLASS BRICK WORK

First class brick work

Brick Work for construction

Steel Bars For RCC Work

inlay work in flooring

glass work

Ceiling with wood work

glass work

Computer work Station

Exterior view of house under Construction work

Stone work on walls

office work

glass work

Nice Brick Work

Compact living room 3 D design with brick wall cladding

Work in Progress

wood work

duplex revit work

glass work

Art work on walls

wood work

rcc concrete breaking work

old building demolition works

old debris disposal works

old building demolisher work

rcc diamond cutting contracting service work

After old chimney demolishing work

old rcc overhead tank dismantling work

Nice Brick Work

work in progres

Construction Material Brick

Tradionally painted work on ceiling